ACEY Ships 10 Sets of ACEY-3753A Ultrasonic Aluminum Wire Bonding Machines to Germany

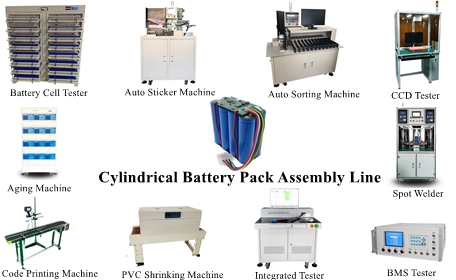

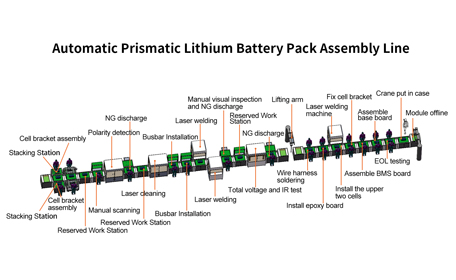

ACEY successfully completed the shipment of a new batch of ACEY-3753A Ultrasonic Wire Bonding Machine to a customer in Europe this week. This delivery marks another milestone in our global supply capability and highlights the strong market demand for our advanced battery production and welding equipment. Shipment Details The shipment includes: Product: Ultrasonic Aluminum Wire Bonding Machine Product Model: ACEY-3753A Quantity: 10 Sets Destination: Germany Application: battery pack factory, EV battery production Manufacturer All our products have passed strict in-house inspection, functional testing, and packaging quality checks to ensure safe and reliable transportation, and have obtained CE certification. The receiving company is a German enterprise specializing in battery pack assembly and energy storage system integration. Their production lines require high-reliability and fine-pitch bonding equipment, and our ACEY-3753A was selected for its proven stability and precision in aluminum wire welding applications. Product Highlights — ACEY-3753A The ACEY-3753A ultrasonic aluminum wire bonding machine is recognized for: Manual (front-end station) loading, automatic identification and positioning, automatic bonding, manual (flowing into the back-end station) unloading. X Y Z module uses precision ball screw drive, the distance repeat positioning accuracy is less than ±0.02mm, and the angle positioning accuracy is ±1°. The control system adopts industrial computer + motion control card to control the operation of the private server motor. The equipment is easy to operate and maintain, the control interface is friendly, and the parameter setting is digital, it is more flexible. Using quick clamp clamping, single button start, easy and safe for personnel to discharge materials. Left-in and right-out can be used for online multi-section track transmission, which can be directly connected to the production line. These technical strengths make the ACEY-3753A a preferred choice for manufacturers seeking improved efficiency and tighter quality control in lithium battery pack production. About ACEY Xiamen Acey New Energy Technology Co., Ltd. is specialized in researching and manufacturing of high-end equipment for lithium-ion batteries. Our business covers battery pack assembly equipment for cylindrical battery & prismatic battery, one-stop solution for semi-automatic battery pack assembly line and automatic battery pack assembly line, battery cell testing equipment, battery pack testing equipment, polymer battery pack assembly equipment, battery environmental safety testing eqipment, battery lab & pilot line, etc. With a rapidly expanding customer base across Europe, Asia, and North America, ACEY will be committed to providing customized solutions to meet the diverse needs of our customers, and continue to focus on the lithium-ion battery industry, striving to become a leading global battery equipment manufacturer.