The automatic stacking machine is a device that can be applied to the stacking process of lithium-ion battery electrode sheet.

Brand:

ACEYItem No.:

ACEY-SSM-CCompliance:

CE CertifiedWarranty:

One Year warranty with lifetime supportOrder(Moq):

1setProduct Origin:

ChinaLead Time:

7daysAutomatic Mobile Phone Batterty Stacking Machine Poch Cell Electrode Stacking Equipment

Description

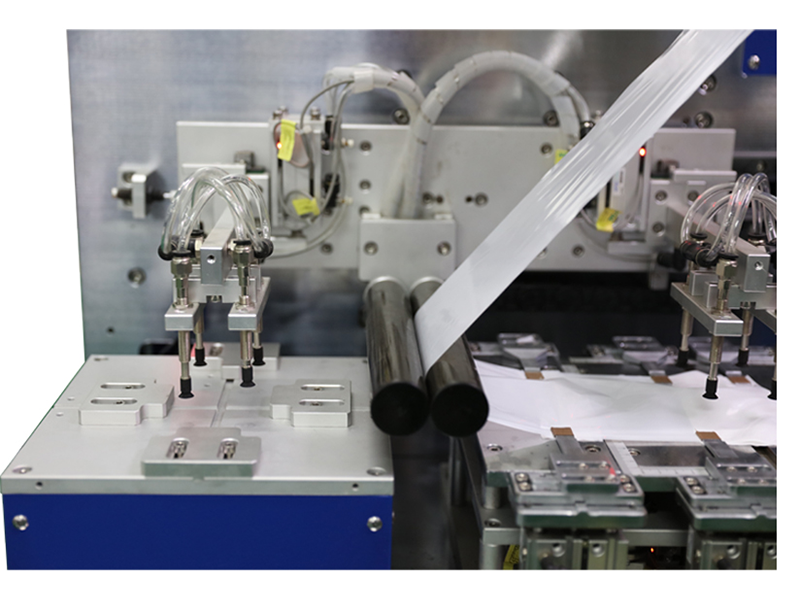

The automatic stacking machine is a device that can be applied to the stacking process of lithium-ion battery pole pieces. The process of manual film loading, subsequent pole piece position correction and lamination is completed automatically, which has the characteristics of high lamination efficiency and high accuracy. The equipment design can stack 200*200mm cells, and different sizes can be realized by adjusting the fixture, which is very suitable for the research and development and sample production of laminated lithium-ion batteries. The equipment adopts a single cantilever structure design, automatic constant tension control of the coil isolation film, and automatic correction control.

Features

1. The number of laminations can be automatically controlled according to the preset;

2. Adopting compatibility design, battery size change can be realized by adjusting the positioning fixture, and the adjustment range is large;

3. PLC control, HMI operation, easy to use and maintain;

4. Pole pieces are manually loaded, automatically positioned, the robot automatically sucks the pieces, and automatically stacks;

5. Automatic servo constant tension control of coiled material diaphragm.

6. Diaphragm automatic photoelectric correction control.

Specification

Model No.

ACEY-SSM-C

manual feeding,

manipulator fetches the stacks, and automatically pulls the diaphragm.

L1100mm*W790mm*H755mm

Lamination method

Z-shaped lamination

Operation method

Lamination accuracy,

neatness ≤±0.3mm

Lamination range

Battery Min. L62mm *W46mm, Max. L200mm*W200mm, without tabs

Lamination thickness

Max.30mm

The number of

laminated layers Max. 500 can be set

Diaphragm roll

diameter Max. 250mm

Diaphragm winding

core 3 inch winding core, pneumatic shaft clamping

Automatic servo

constant tension control of coiled material diaphragm.

Diaphragm automatic

photoelectric correction control.

Power supply voltage

single-phase AC220V±10% (110VAC can be customized), frequency 50Hz/60Hz, power

0.6KW

Air source 0.5~0.8MPa

compressed air

Using environment The

recommended environment temperature is 25±3℃, humidity is 30~90RH, no vibration

and electromagnetic interference

Dimensions

Weight

300kg