Categories

New Blog

One Of The Ten Key Equipment For Lithium Batteries: Pulping Equipment

September 06 , 2024One Of The Ten Key Equipment For Lithium Batteries: Pulping Equipment

What is pulping

Pulping is the active substance, conductive agent, dispersant, binder, additives and other components in accordance with a certain proportion and order into the mixer, in the stirring paddle and dispersion disc turning, kneading, shear and other mechanical action mixed in the 1 period, the formation of uniform and stable solid-liquid suspension system.

1.The importance of the pulping process

The upper limit of the performance of lithium-ion batteries is determined by the chemical system used (positive active material, negative active material, electrolyte), and the actual performance depends on the microstructure of the pole piece. The microstructure of the pole piece is mainly determined by the microstructure of the slurry and the coating process, which is dominated by the microstructure of the slurry. Therefore, there is a widely recognized statement that in the impact of the manufacturing process on the performance of lithium-ion batteries, the impact of the previous process accounts for at least 70%, while the impact of the pulping process in the previous process accounts for at least 70%, that is, the impact of the pulping process accounts for about half.

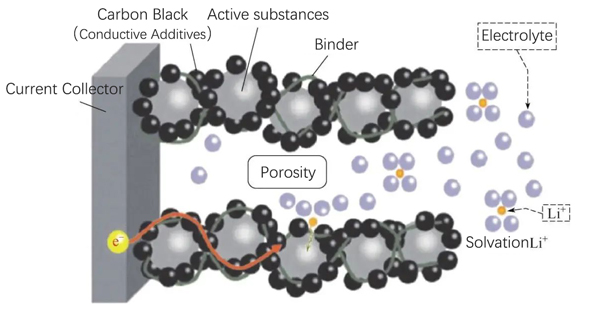

The electrodes of lithium-ion batteries need to achieve good electron and ion transmission, which requires that the distribution state of active materials, conductive agents and binders in the electrodes meet certain requirements. The ideal distribution state of each material in the electrode is shown in Figure 1, that is, the active material is fully dispersed, the conductive agent is fully dispersed and in full contact with the active material to form a good electronic conductive network, and the binder is evenly distributed in the electrode and bonds the active material and the conductive agent to make the electrode a whole.

Figure 1-Ideal distribution of materials in lithium-ion battery electrodes

Double planetary mixer

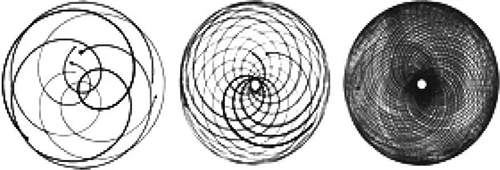

The working principle of the double planetary mixer is to use 2~3 slow mixing paddles to do a combination of revolution and autobiography, so that the trajectory of the blade can cover the entire space inside the mixing barrel.

The trajectory of the slow blade of a double planetary mixer when it combines revolution and rotation.

The outstanding advantage of the double planetary mixer is that it can easily adjust the feeding sequence, speed and time and other process parameters to adapt to different material characteristics, and can be easily reworked when the slurry characteristics do not meet the requirements, adaptability and flexibility Very strong. In addition, when the variety is switched, the cleaning of the double planetary mixer, especially the small mixer, is relatively simple.

Acey New Energy is specialized in researching and manufacturing of high-end equipment for lithium-ion batteries. We can not only provide production equipment for cylindrical cell, coin cell, and pouch cell lithium-ion batteries, but also provide one-stop solutions for lithium battery production line. If you are new to the lithium-ion battery industry and want to build your own lithium-ion battery production line or lithium-ion battery pack assembly line, we can provide you with professional technical support and guidance, please feel free to contact us!