Categories

New Blog

What Is A Lithium-Ion Battery Energy Storage System?

August 16 , 2024

Definition

The lithium-ion battery pack, also known as the battery module, is a manufacturing process for lithium-ion batteries. It involves packaging, encapsulating, and assembling multiple lithium-ion cells by connecting them in series and parallel. The process also considers factors such as mechanical strength, thermal management, and Battery Management System (BMS) compatibility.

Key technologies in the pack process include overall structural design, welding and processing control, protection levels, and active thermal management systems. When two or more cells are connected in series or parallel to form a specific shape as per customer requirements, it is referred to as a pack.

Components of a Battery Pack

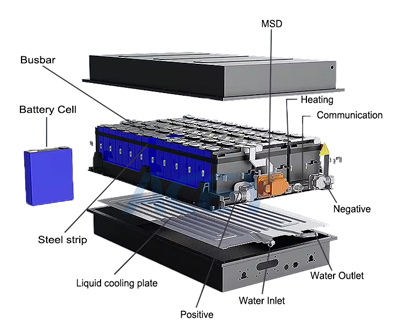

The battery pack mainly consists of single battery modules, electrical systems, thermal management systems, boxes and BMS, etc.

Prismatic Battery Pack Structure Diagram

Energy storage high-voltage wiring harness

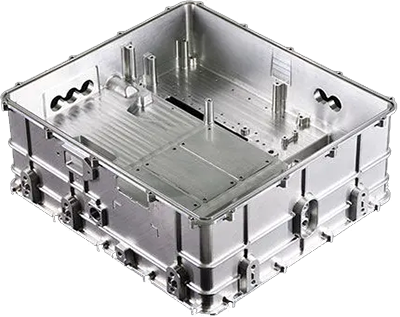

Battery pack case body

Characteristics of Battery Pack

How to ensure that the battery has a high degree of consistency?

This requires the use of specialized battery charge discharge test equipment to sort the battery capacity and screen its performance. By performing charge and discharge tests on each lithium battery, the computer records the data of each test point, and thus obtains the capacity and internal resistance of each battery, and determines the quality grade of the lithium battery. The battery can quickly and accurately evaluate the capacity and performance of the battery through efficient cycle charge and discharge tests.

Methods of Pack Formation

▶Series and Parallel Configuration:

The battery module is formed by connecting individual cells in series and parallel. Parallel connections increase capacity while keeping the voltage constant, while series connections increase voltage while keeping the capacity constant.

▶Cell Requirements:

Based on design requirements, select the corresponding cells. The batteries used in parallel or series must be of the same type, model, and have similar capacities, internal resistance, and voltage, with differences not exceeding 2%. Regardless of whether soft-pack batteries or cylindrical batteries are used, multiple cells need to be combined in series.

▶Pack Process:

The pack process can be achieved through two main methods:

Handheld/Automatic Fiber Laser Welding Machine

Considering production yield, efficiency, and the internal resistance of connection points, laser welding has become the preferred choice for many battery manufacturers.

Acey New Energy is specialized in researching and manufacturing of high-end equipment for lithium-ion battery cell production and pack assembly. They can not only provide cheap and best automatic laser welding machine for lithium ion batteries, but also provide one-stop solutions for lithium battery pack assembly. In addition, they also have a professional engineering team that can provide free online technical support and guidance.

Understanding Battery Pack Technical Parameters

| Project Name | Parameter Indicators |

| Combination Mode | 1P24S |

| Rated Capacity | 280Ah |

| Rated Voltage | 76.8V |

| Rated Energy | 21.504kWh |

| Maximum Discharge Rate | 0.5CP |

| Weight | 138±3kg |

▶Combination Mode: 1P24S

"S" stands for series-connected cells, and "P" stands for parallel-connected cells. 1P24S indicates 24 cells in series and 1 cell in parallel, resulting in a rated voltage of 3.2V * 24 = 76.8V.

The rated capacity of a battery is the amount of energy it can store and discharge under specified working conditions over time. It is the product of discharge current (A) and discharge time (h). Therefore, 280Ah indicates that the battery can continuously discharge at a maximum rate of 0.5C for 2 hours.

Rated energy (Wh) = nominal capacity (Ah) * nominal voltage (V), so the total energy that a battery can release is related to both capacity and voltage.

The above is a detailed analysis of the energy storage lithium battery Pack. If you are new in lithium ion battery industry, and want to build your own lithium ion battery production line or lithium ion battery pack assembly line, then ACEY, which adheres to strict quality control and thoughtful customer service, will be your best helper on the road to success!