What Are The Process Flow Of Prismatic Lithium Battery Pack Production Line?

Lithium battery pack production process is relatively complex, pack is the key to power battery system production, design and application, is connected to the upstream core production and downstream application of the core link, that lithium ion battery pack production line what process flow?

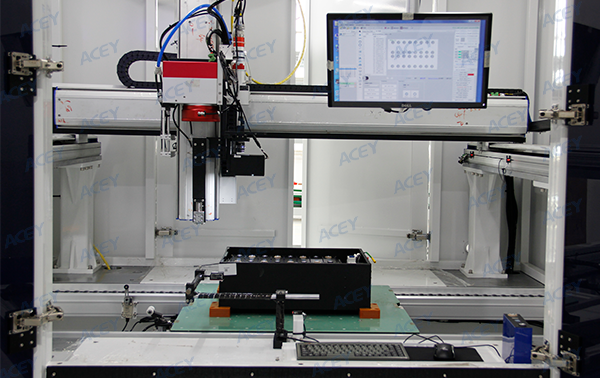

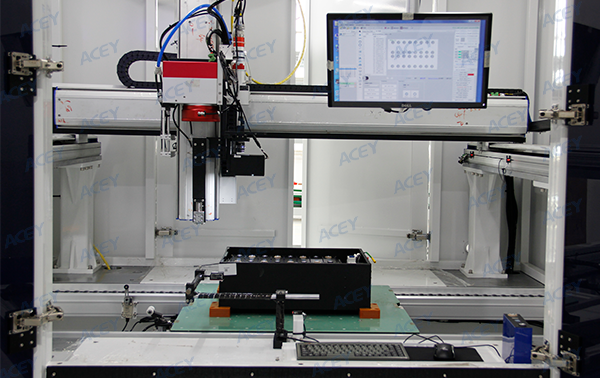

Automatic Prismatic Lithium Battery Pack Assembly Line

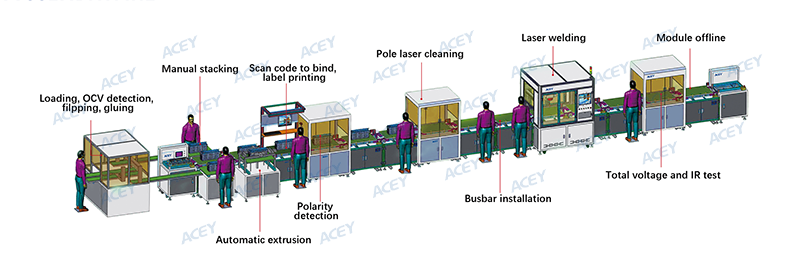

What are the process flow of lithium battery pack production line?

-

Cell sorting process

-

Stacking and extrusion process

-

Polarity testing process

-

Laser cleaning process

-

Automatic laser welding process

-

Total voltage&internal resistance test process

-

Pack packaging process

-

BMS testing process

-

Comprehensive test process

-

Aging test process

Automatic Prismatic Lithium Battery Pack Assembly Line(Project Display)

Composition of prismatic lithium battery pack

Prismatic battery pack includes battery cells, busbar, flexible connection, protection board, outer packaging, output (including connectors), bracket, end side plate, steel or plastic tape, wiring harness and other auxiliary materials, which together make up the pack.

The characteristics of lithium battery pack

-

The battery pack requires a high degree of consistency of lithium batteries.

-

The cycle life of the battery pack is lower than the cycle life of a single battery.

-

Used under limited conditions (including charging and discharging current, charging method, temperature, etc.)

-

The battery voltage and capacity of lithium battery pack are greatly increased after molding, so it must be protected and monitored for charging equalization, temperature, voltage and over-current.

-

The lithium battery pack must meet the voltage and capacity requirements of the design.

Prismatic lithium battery pack assembly is realized in two ways, one is through laser welding, which is a common welding method, the advantage is better reliability, but not easy to replace. The second is through the elastic metal sheet contact, the advantage is no welding, battery replacement is easy, the disadvantage is that it may lead to poor contact.

Laser Welding Process

Automatic fiber laser welding machine is a very important part in the lithium battery pack assembly line. Laser welding has the following advantages in lithium battery pack assembly:

-

High Precision and Consistency: Laser welding allows for precise control of weld location and depth, ensuring consistency across all welds. This is crucial for the stability and safety of lithium battery connections.

-

Small Heat-Affected Zone (HAZ): Laser welding has a small HAZ, minimizing the impact on the internal structure and electrochemical performance of the batteries. This helps in preserving battery life and performance.

-

High Efficiency: Laser welding is fast, significantly improving production efficiency and reducing production time and costs.

-

Non-Contact Process: As a non-contact process, laser welding avoids contamination and wear that can occur with physical contact.

-

High Automation Level: Laser welding can be easily integrated into automated production lines, making it suitable for large-scale manufacturing and enhancing efficiency and product consistency.

-

High Strength: The welds produced by laser welding typically have high strength and reliability, capable of withstanding significant mechanical stress and vibrations.

-

Versatility: Laser welding can handle different materials (such as aluminum, copper, etc.) and various material thicknesses, offering good adaptability.

From the lithium battery single cell to the battery pack production line in the whole process, the degree of automation of the assembly line is a key factor in determining product quality and production efficiency.

Acey New Energy is specialized in researching and manufacturing of high-end equipment for lithium-ion battery cell and pack. We can not only provide equipment for cylindrical, pouch cell, prismatic lithium ion battery pack assembly, but also provide one-stop solution for cylindrical, pouch cell&prismatic lithium battery pack assembly line, if you are new in lithium ion battery industry, and want to build your own lithium ion battery production line or lithium ion battery pack assembly line, we can provide you professional technical support and guidance, please feel free to contact us!